BUFFER VESSELS

Vertical Buffer Vessels

Manufactured in Carbon Steel or Stainless Steel, buffer vessels are manufactured to the pressure directive PED 2014/68/EU

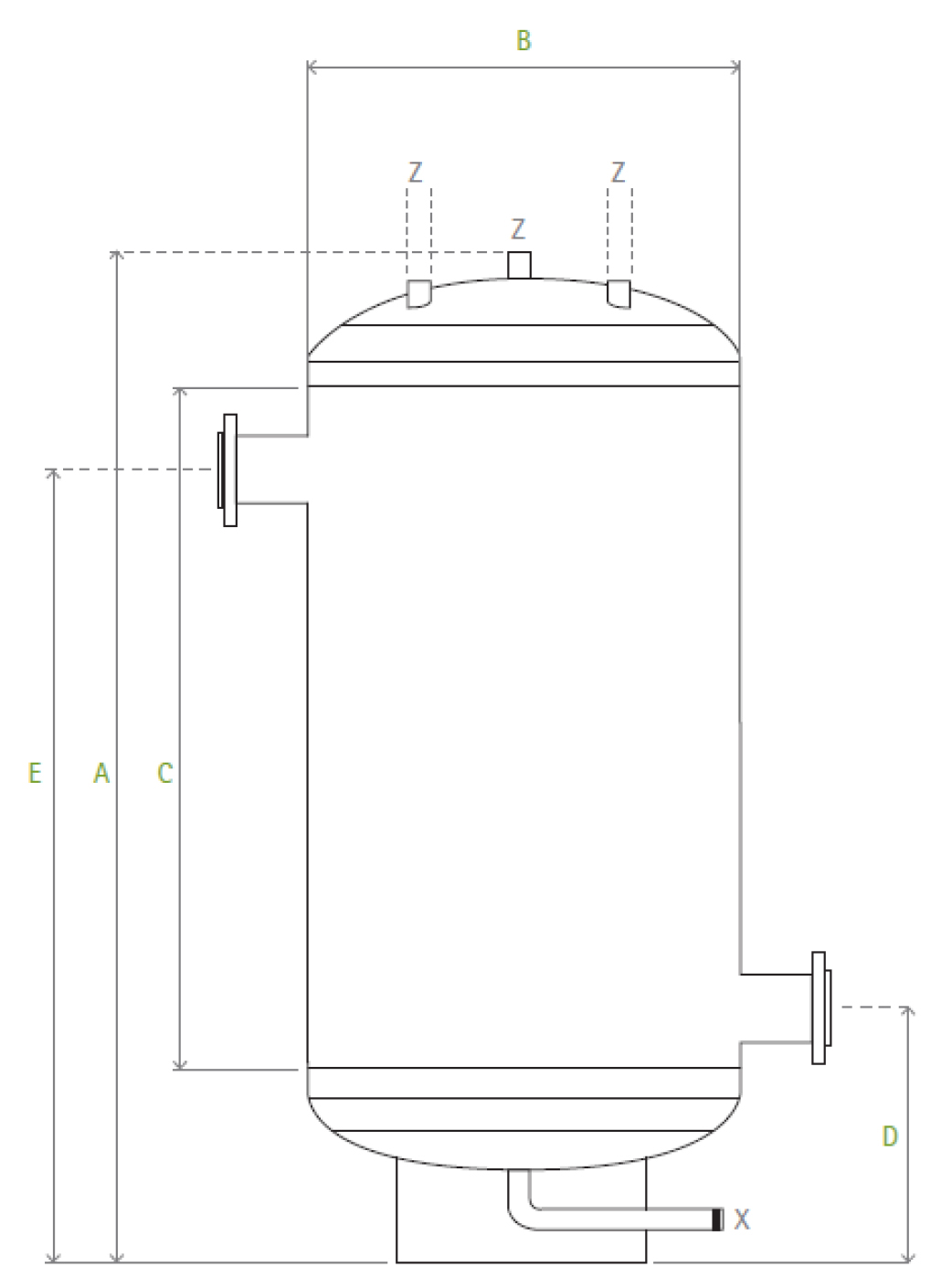

The drawing and chart are for guidance only, buffer vessels can be manufactured to any size from 10 litre to 100,000 litre, connections can be situated anywhere you require, diameter and height can be altered to suit your particular requirements.

Installation

- Unless specifically ordered for outside, positioning of the vessel must be indoors.

- The base must be level and adequate to support the unit.

- Vessels ordered specifically with inspection covers, please ensure enough room exists to gain access to the opening.

- Pipe work connected to the vessel must be supported to prevent unnecessary strain on the buffer vessels connections.

- Isolation valves are to be installed to enable servicing and maintenance.

- Ensure adequate venting for air removal during filling and venting.

Commissioning & Operation

- Do not operate the buffer vessel at pressures or temperatures in excess of those specified as a standard this is 10 bar and 110 degrees Centigrade.

- Do not subject the vessel to any vacuums.

- If the vessel is open vented and shares a common vent with other vessels install a 3-way valve.

- Upon initial system fill open all isolation valves connected to the vessel.

- Check all flanges and screwed joints for tightness.

- All liquid is to be drained from the vessel when the unit is out of operation (long periods) to prevent freezing or corrosion.

Size Chart

| Litre | A | B | C | D | E | Z | X |

|---|---|---|---|---|---|---|---|

| 100 | 1050 | 406 | 570 | 396 | 740 | 25 | 25 |

| 200 | 1280 | 500 | 773 | 410 | 950 | 25 | 25 |

| 500 | 1450 | 750 | 832 | 460 | 1060 | 25 | 25 |

| 750 | 2010 | 750 | 1392 | 460 | 1620 | 25 | 25 |

| 1000 | 1890 | 900 | 1284 | 460 | 1510 | 25 | 25 |

| 1250 | 2280 | 900 | 1674 | 460 | 1900 | 25 | 25 |

| 1500 | 1700 | 1200 | 882 | 575 | 1180 | 25 | 25 |

| 2000 | 2140 | 1200 | 1324 | 575 | 1620 | 25 | 25 |

| 2500 | 2590 | 1200 | 1772 | 575 | 2070 | 25 | 25 |

| 3000 | 2210 | 1512 | 1166 | 690 | 1610 | 25 | 25 |

| 3500 | 2500 | 1512 | 1460 | 690 | 1930 | 25 | 25 |

| 4000 | 2780 | 1512 | 1740 | 690 | 2210 | 25 | 25 |

| 4500 | 2430 | 1800 | 1158 | 840 | 1720 | 25 | 25 |

| 5000 | 2630 | 1800 | 1358 | 840 | 1920 | 25 | 25 |

| 6000 | 2600 | 2000 | 1268 | 870 | 1860 | 25 | 25 |

| 8000 | 3230 | 2000 | 1898 | 870 | 2490 | 25 | 25 |

| 10000 | 3860 | 2000 | 2528 | 870 | 3120 | 25 | 25 |

| 15000 | 3870 | 2512 | 2340 | 1030 | 2990 | 25 | 50 |

| 20000 | 4880 | 2512 | 3350 | 1030 | 4000 | 25 | 50 |